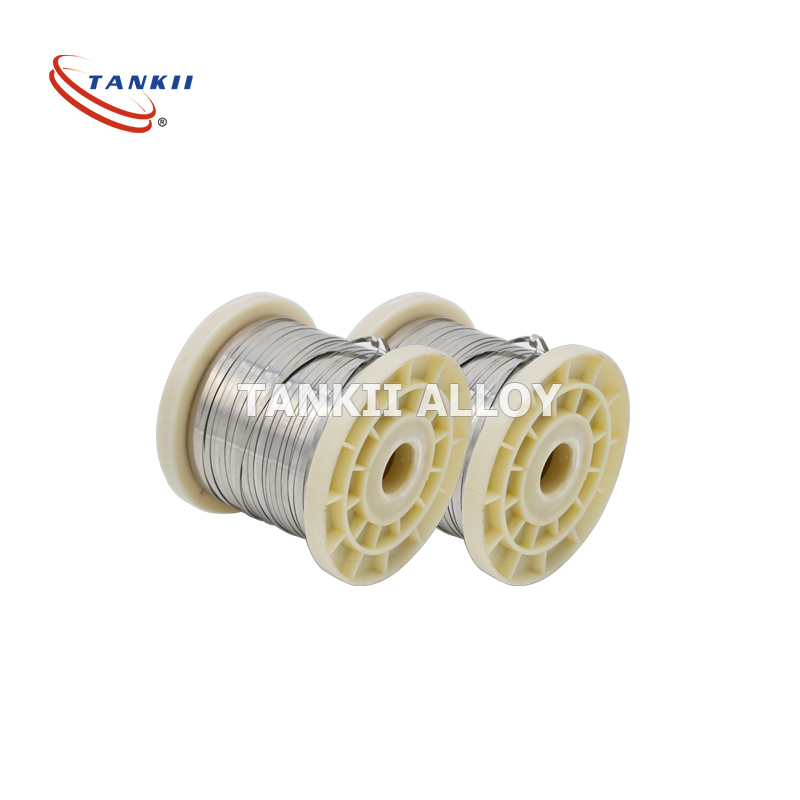

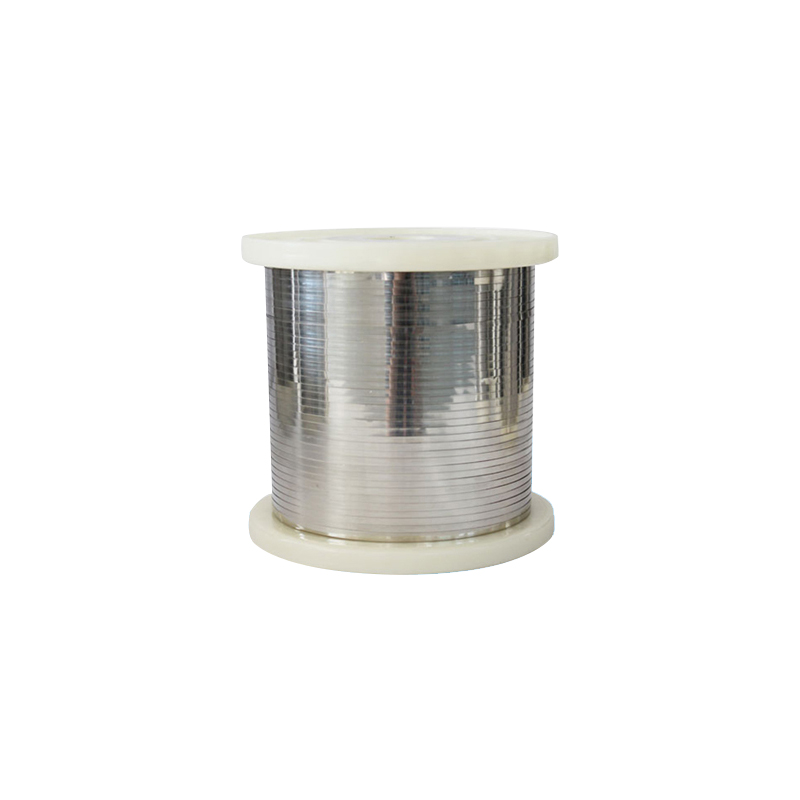

Utepe wa kinyesi wa 0.2×2.5mm, Waya Bapa ya Kupasha Joto ya Upinzani wa 0cr23al5 yenye Cheti cha ISO9001

Waya Bapa ya Kupasha Joto ya Upinzani ya 0cr23al5 yenye Cheti cha ISO9001

Waya ya Upinzani iliyotengenezwa kwa Aloi za Chrome za Nikeli, Aloi za Chuma za Chrome za Nikeli, Aloi za Alumini za Chrome za Chuma, Aloi za Nickeli za Shaba.

Hutumika sana katika hita, kipengele cha kupasha joto na kipingamizi, n.k.

NiCr 80/20, NiCr 70/30, NiCr 60/15, NiCr 35/20

FeCrAl15-5, FeCrAl20-5, FeCrAl 25-5, nk…

Constantan, Aloi 30, Aloi 60, Aloi 90, n.k.

Upinzani wa Umeme kutoka 0.02 u ohm/m-1.53 u ohm/m

Halijoto ya Uendeshaji kuanzia 200 C hadi 1400 C

Tafadhali kuwa huru kuwasiliana nasi ikiwa una swali lolote.

NiCr:

RESISTOHM 20, RESISTOHM 30, RESISTOHM 40, RESISTOHM 60, RESISTOHM 70, RESISTOHM 80

FeCrAl:

RESISTOHM 125, RESISTOHM 135, RESISTOHM 140,

RESISTOHM 145, RESISTOHM 153

CuNi

Constantan, Cuprothal 5, Cuprothal 10, Cuprothal 15, Cuprothal 30, Eurica

| Daraja la Aloi ya FeCrAl | Muundo wa Kemikali % | |||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Re | Wengine |

| kiwango cha juu (≤) | ||||||||||

| 1Cr13Al4 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 12.5-15.0 | —- | 3.5-4.5 | 0.1 | Bal. |

| 0Cr15Al5 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 14.5-15.5 | —- | 4.5-5.3 | 0.1 | Bal. |

| 0Cr25Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 23.0-26.0 | ≤0.60 | 4.5-6.5 | 0.1 | Bal. |

| 0Cr23Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 20.5-23.5 | ≤0.60 | 4.2-5.3 | 0.1 | Bal. |

| 0Cr21Al6 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 19.0-22.0 | ≤0.60 | 5.0-7.0 | 0.1 | Bal. |

| 0Cr21Al4 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 21.0-23.0 | ≤0.60 | 3.0-5.2 | 0.1 | Bal. |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.60 | 21.0-23.0 | ≤0.60 | 5.0-7.0 | 0.1 | Bal. |

| 0Cr27Al7Mo2 | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.40 | 26.5-27.8 | ≤0.60 | 6.0-7.0 | 0.1 | Bal. |

![]()

![]()

![]()

![]()

Muundo wa Kemikali na Sifa:

| Sifa/Daraja | NiCr 80/20 | NiCr 70/30 | NiCr 60/15 | NiCr 35/20 | NiCr 30/20 | |

| Kemikali Kuu Muundo(%) | Ni | Bal. | Bal. | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 |

| Cr | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 | |

| Fe | ≤ 1.0 | ≤ 1.0 | Bal. | Bal. | Bal. | |

| Kufanya Kazi kwa Upeo Halijoto (ºC) | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Upinzani katika 20ºC (μΩ · m) | 1.09 | 1.18 | 1.12 | 1.04 | 1.04 | |

| Uzito (g/cm3) | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Uendeshaji wa joto (KJ/m· h· ºC) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Mgawo wa joto Upanuzi(α × 10-6/ºC) | 18 | 17 | 17 | 19 | 19 | |

| Kiwango cha Kuyeyuka (ºC) | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Urefu (%) | > 20 | > 20 | > 20 | > 20 | > 20 | |

| Muundo wa Mikrografiki | austenite | austenite | austenite | austenite | austenite | |

| Sifa ya Sumaku | isiyo na sumaku | isiyo na sumaku | isiyo na sumaku | isiyo na sumaku | isiyo na sumaku | |

![]()

![]()

![]()

![]()

| Daraja la Aloi za CuNi | Upinzani wa umeme (20°Ω mm² /m) | mgawo wa upinzani wa halijoto (10^6/digrii) | Uzito g/mm² | Halijoto ya juu zaidi (shahada) | Kiwango cha kuyeyuka (shahada) |

| CuNi1 | 0.03 | < 1000 | 8.9 | 200 | 1085 |

| CuNi2 | 0.05 | < 1200 | 8.9 | 200 | 1090 |

| CuNi6 | 0.10 | < 600 | 8.9 | 220 | 1095 |

| CuNi8 | 0.12 | < 570 | 8.9 | 250 | 1097 |

| CuNi10 | 0.15 | < 500 | 8.9 | 250 | 1100 |

| CuNi14 | 0.20 | < 380 | 8.9 | 300 | 1115 |

| CuNi19 | 0.25 | < 250 | 8.9 | 300 | 1135 |

| CuNi22 | 0.30 | < 160 | 8.9 | 300 | 1150 |

| CuNi30 | 0.35 | < 100 | 8.9 | 350 | 1170 |

| CuNi34 | 0.40 | -0 | 8.9 | 350 | 1180 |

| CuNi40 | 0.48 | ± 40 | 8.9 | 400 | 1280 |

| CuNi44 | 0.50 | < -6 | 8.9 | 400 | 1280 |

![]()

![]()

![]()

![]()

Aina za bidhaa

-

Simu

-

Barua pepe

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Juu