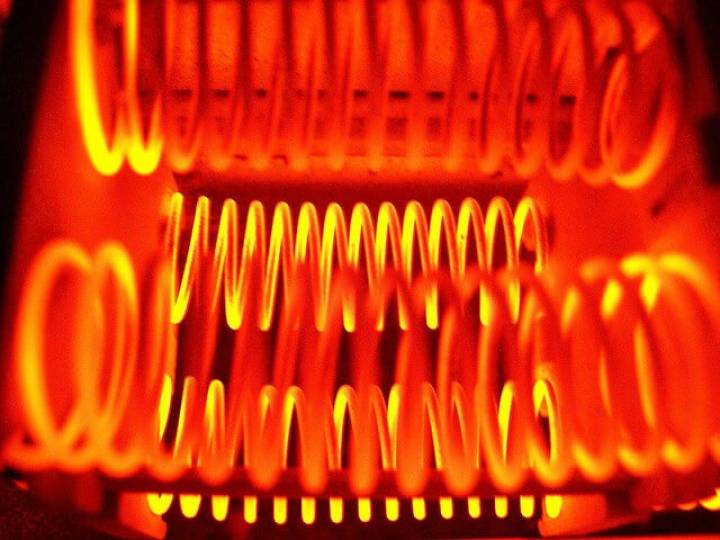

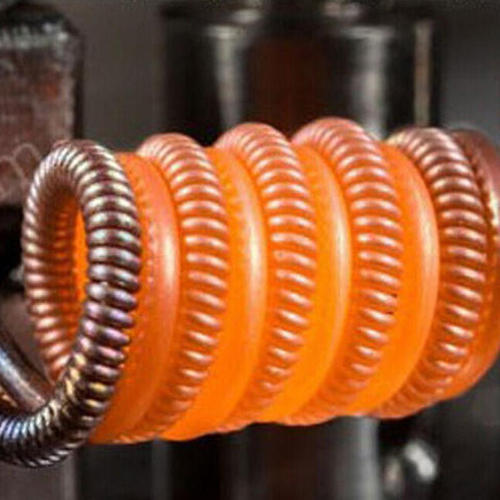

Koili ya kupokanzwa ya waya ya jiko la umeme ya FeCrAl 0Cr25Al5

Sifa Kuu ya waya ya upinzani wa joto

| Aina ya Aloi | Kipenyo (mm) | Upinzani (μΩm)(20°C) | Mvutano Nguvu (N/mm²) | Urefu (%) | Kupinda Nyakati | Max.Endelevu Huduma Halijoto(°C) | Maisha ya Kazi (saa) |

| Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

| JINA | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| KEMIKALI KUU | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| MUUNDO | Re | inayofaa | inayofaa | inayofaa | inayofaa | inayofaa | inayofaa | inayofaa |

| Fe | Pumziko | Pumziko | Pumziko | Pumziko | Pumziko | Pumziko | Pumziko | |

| Nambari 0.5 | Mwezi 1.8-2.2 | |||||||

| JOTO LA JUU (oC) | 650 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Upinzani 20oC (μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| UZITO (g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| UBADILISHAJI WA JOTO | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| KIWANGO(KJ/m·h·oC) | ||||||||

| kiwango cha upanuzi (α×10-6/oC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| kiwango cha kuyeyuka (oC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| nguvu ya mvutano (N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| urefu (%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| tofauti ya eneo(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| masafa ya kupinda (F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| ugumu (HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| muundo wa mikrografi | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| sifa ya sumaku | Sumaku | Sumaku | Sumaku | Sumaku | Sumaku | Sumaku | Sumaku | |

| Kipenyo(mm) | Uvumilivu (mm) | Kipenyo(mm) | Uvumilivu (mm) |

| 0.03-0.05 | ± 0.005 | >0.50-1.00 | ± 0.02 |

| >0.05-0.10 | ± 0.006 | >1.00-3.00 | ± 0.03 |

| >0.10-0.20 | ± 0.008 | >3.00-6.00 | ± 0.04 |

| >0.20-0.30 | ± 0.010 | >6.00-8.00 | ± 0.05 |

| >0.30-0.50 | ± 0.015 | >8.00-12.0 | ± 0.4 |

| Unene (mm) | Uvumilivu (mm) | Upana(mm) | Uvumilivu (mm) |

| 0.05-0.10 | ± 0.010 | 5.00-10.0 | ± 0.2 |

| >0.10-0.20 | ± 0.015 | >10.0-20.0 | ± 0.2 |

| >0.20-0.50 | ± 0.020 | >20.0-30.0 | ± 0.2 |

| >0.50-1.00 | ± 0.030 | >30.0-50.0 | ± 0.3 |

| >1.00-1.80 | ± 0.040 | >50.0-90.0 | ± 0.3 |

| >1.80-2.50 | ± 0.050 | >90.0-120.0 | ± 0.5 |

| >2.50-3.50 | ± 0.060 | >120.0-250.0 | ± 0.6 |

Sisi ni watengenezaji wa waya za upinzani wa joto

Waya wa FeCrAL, waya wa NiCr, waya wa CuNi:

II Faida Kuu na Matumizi

A. Kigezo cha kimwili:

1) Kipenyo cha waya: 0.025 ~ 15mm

2) Nikeli safi ina uwezo wa kuhimili halijoto ya juu bila kuzorota. Utendaji wa kiwango cha juu zaidi

halijoto ni takriban 600°C

3) Waya za nikeli zinapatikana katika muundo wa nyuzi moja au nyuzi nyingi. Hutolewa kutoka kwa bidhaa iwe tupu, au iliyowekewa insulation

B. Sifa:

1) Unyoofu bora

2) Hali ya uso yenye usawa na nzuri bila madoa

3) Uwezo bora wa kutengeneza koili

C. Matumizi makuu na madhumuni ya jumla:

1) Waya huu unaweza pia kutumika sana katika vifuniko maalum vya transistor, anodi za mirija ya kielektroniki,

waya za chuma za vijenzi vya kielektroniki / waya za chuma za taa na waya wa matundu. Pia hutumika katika umbo la utepe kwa aina mbalimbali za waya.

programu ikiwa ni pamoja na betri za Ni-Cd

2) Pia hutumika kwa nyaya, Waya wa Risasi kwa taa, vifaa vya kushikilia mirija ya kielektroniki, waya za kuunganisha umeme kwa kitambaa cha waya

ambapo halijoto ni kubwa kuliko zile zinazofaa kwa shaba, ufumaji wa waya

3) Matumizi ya kawaida ni pamoja na: vizuizi vya vipengele vya kupasha joto kama vile katika oveni, plastiki, vifaa vya kutolea nje, na tanuru.

Viunganishi vya nyuzi na waya za risasi katika tasnia ya taa

Aina za bidhaa

-

Simu

-

Barua pepe

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Juu