Karibu kwenye tovuti zetu!

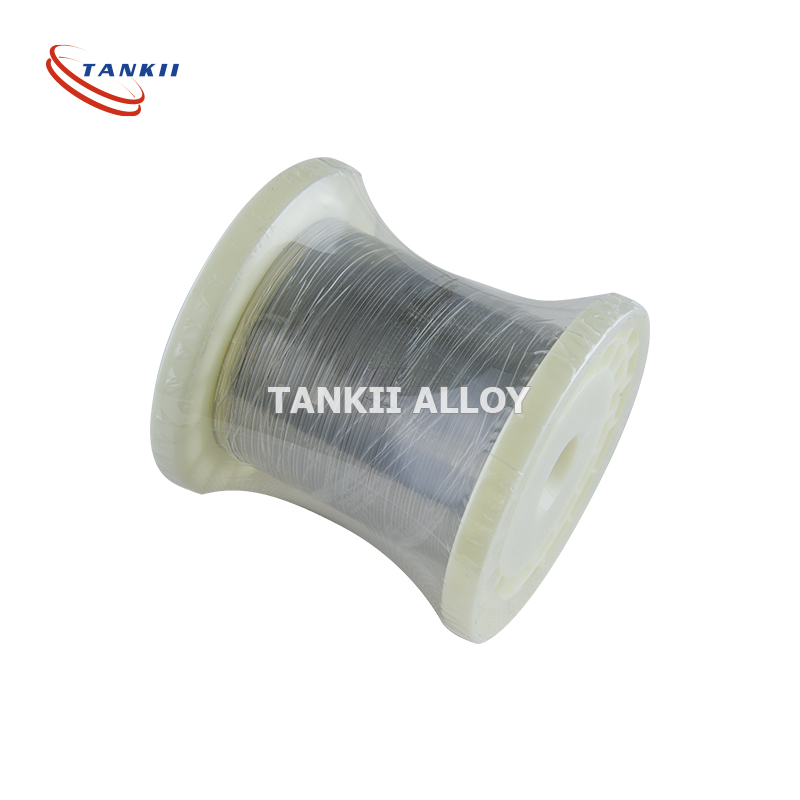

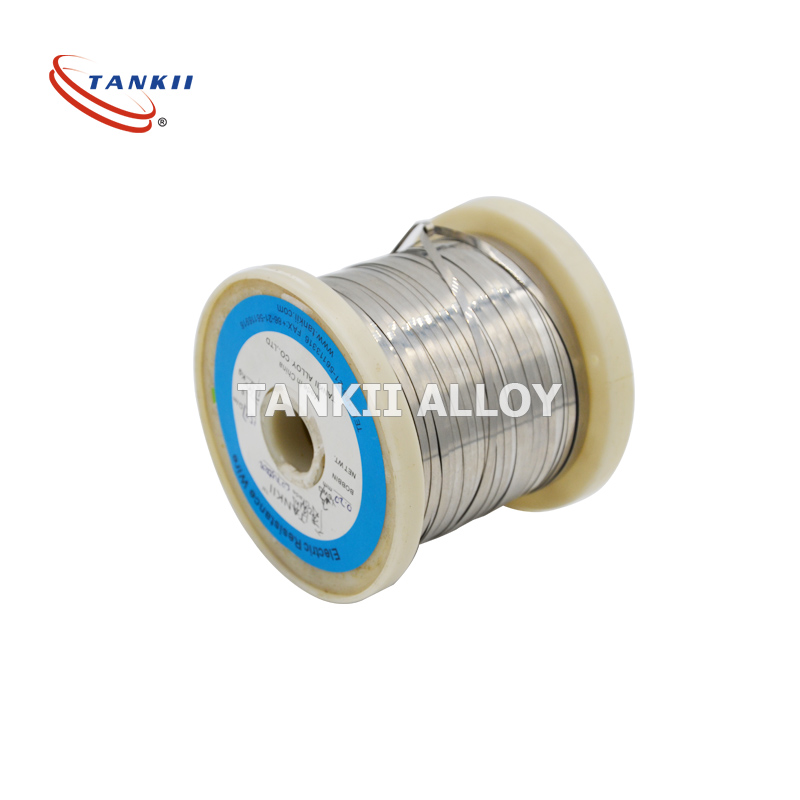

Waya Bapa Aloi ya Nicr/Fecral Ni80cr20, nicr7030, nicr6015,0cr25al5,0cr23al5,0cr21al6nb

| Hali | Rangi angavu / Nyeupe ya Asidi / Oksidi |

| Kipenyo | 0.018mm-1.6mm katika Spool, 1.5mm-8mm katika Coil, 8mm-60mm katika Fimbo |

| Kipenyo cha Waya Mzunguko | 0.018mm – 10mm |

| Utepe | Unene 0.01-2mm, Upana 0.5-5mm |

| Ukanda | Unene 0.001-7mm, Upana 1-450mm |

| Daraja | 1Cr13Al4,0Cr25Al5, 0Cr21Al6,0Cr23Al5, 1Cr20Al3,0Cr21Al6Nb, 0Cr27Al7Mo2 |

| Kiwango cha Uzalishaji | ASTM B603, DIN 17470, JIS C2520, GB/T 1234 |

| Sifa | Utendaji Imara, Kupambana na Oksidasheni, Upinzani wa Kutu, Utulivu wa Joto la Juu, Uwezo Bora wa Kutengeneza Koili, Sare na Hali Nzuri ya Uso Bila Madoa |

| Matumizi | Vipengele vya Kupasha Joto vya Upinzani; Nyenzo katika Umeme; Vifaa vya Nyumbani; Viwanda vya Mitambo na viwanda vingine. |

| Muundo wa metali wa Nichrome huwapa unyumbufu mzuri sana wakati wa baridi | |

| Faida Zetu | Ubora wa Juu, Muda Mfupi wa Uwasilishaji, MOQ Ndogo |

![]()

![]()

![]()

![]()

Sifa Kuu za Waya za Upinzani wa Nichrome:

| Utendaji wa Majina ya Aloi | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 1Cr20Al3 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

|---|---|---|---|---|---|---|---|---|

| Kuu Kemikali muundo | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| Re | inayofaa | inayofaa | inayofaa | inayofaa | inayofaa | inayofaa | inayofaa | |

| Fe | Pumziko | Pumziko | Pumziko | Pumziko | Pumziko | Pumziko | Pumziko | |

| Nambari 0.5 | Mwezi 1.8-2.2 | |||||||

| Halijoto ya juu zaidi ya huduma endelevu ya kipengele | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Upinzani katika 20ºC (μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| Uzito (g/cm3) | 7.40 | 7.10 | 7.16 | 7.25 | 7.35 | 7.10 | 7.10 | |

| Upitishaji joto (KJ/m·h·ºC) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| Upanuzi wa mgawo wa mistari (α×10)-6/ºC) | 15.4 | 16.0 | 14.7 | 15.0 | 13.5 | 16.0 | 16.0 | |

| Kiwango cha kuyeyuka (takriban)(ºC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Nguvu ya mvutano (N/mm)2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| Urefu wakati wa kupasuka (%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Tofauti ya eneo(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| Masafa ya kupinda (F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| Ugumu (HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Muda wa Huduma Endelevu (Saa/ºC) | – | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

| Muundo wa maikrografi | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| Sifa za sumaku | Sumaku | Sumaku | Sumaku | Sumaku | Sumaku | Sumaku | Sumaku | |

![]()

![]()

![]()

![]()

Andika ujumbe wako hapa na ututumie

Aina za bidhaa

-

Simu

-

Barua pepe

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Juu