Karibu kwenye tovuti zetu!

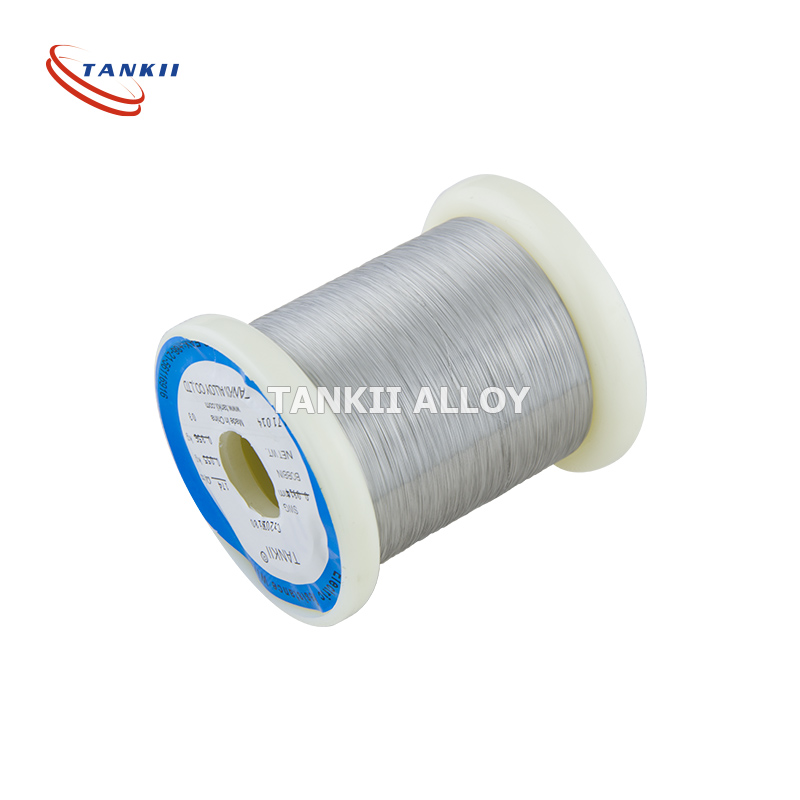

Waya ya Kupasha Joto ya GNC108/Nichrome/X20h80 / Waya Iliyounganishwa kwa Upinzani Unaonyumbulika kwa Kipingamizi na Kipasha Joto

Waya za Kupasha Joto za GNC108/Nichrome/X20H80 / Waya Zilizounganishwa kwa Upinzani Unaonyumbulika

Maelezo

| Aloi | Ujenzi wa Kamba Sawa, mm | Upinzani,Ω/m | Kipenyo cha Kamba Nomino, mm | Mita kwa Kilo |

| NiCr 80/20 | 19×0.544 | 0.233-0.269 | 26 | |

| NiCr 80/20 | 19×0.61 | 0.205-0.250 | ||

| NiCr 80/20 | 19×0.523 | 0.276-0.306 | 2.67 | 30 |

| NiCr 80/20 | 19×0.574 | 2.87 | 25 | |

| NiCr 80/20 | 37×0.385 | 0.248-0.302 | 2.76 | 26 |

| NiCr 60/15 | 19×0.508 | 0.286-0.318 | ||

| NiCr 60/15 | 19×0.523 | 0.276-0.304 | 30 | |

| Ni | 19×0.574 | 0.020-0.027 | 2.87 | 21 |

Maelezo

| Sifa/Daraja | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

| Muundo Mkuu wa Kemikali | Ni | Pumziko | Pumziko | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 |

| Cr | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 | |

| Fe | ≤ 1.0 | ≤ 1.0 | Pumziko | Pumziko | Pumziko | |

| Halijoto ya juu zaidi ya huduma endelevu ya kipengele | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Upinzani katika 20oC (μΩ · m) | 1.09 | 1.18 | 1.12 | 1.04 | 1.04 | |

| Uzito (g/cm3) | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Upitishaji joto (KJ/m· h· oC) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Upanuzi wa mgawo wa mistari (α × 10-6/oC) | 18 | 17 | 17 | 19 | 19 | |

| Kiwango cha kuyeyuka (takriban)(oC) | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Urefu wakati wa kupasuka (%) | > 20 | > 20 | > 20 | > 20 | > 20 | |

| Muundo wa maikrografi | austenite | austenite | austenite | austenite | austenite | |

| Sifa za sumaku | isiyo na sumaku | isiyo na sumaku | isiyo na sumaku | isiyo na sumaku | isiyo na sumaku | |

| Muundo wa Kemikali | Nickel, Chrome |

| Hali | Rangi angavu/nyeupe yenye asidi/iliyooksidishwa |

| Daraja | Ni80Cr20, Ni70/30, Ni60Cr15, Ni60Cr23, Ni35Cr20Fe, Ni30Cr20 Ni80, Ni70,Ni60, Ni40, |

| Faida | Muundo wa metali wa Nichrome huwapa unyumbufu mzuri sana wakati wa baridi. |

| Sifa | Utendaji thabiti; Kinga dhidi ya oksidi; Upinzani wa kutu; Uthabiti wa halijoto ya juu; Uwezo bora wa kutengeneza koili; Hali ya uso sare na mzuri bila madoa. |

Andika ujumbe wako hapa na ututumie

Aina za bidhaa

-

Simu

-

Barua pepe

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Juu