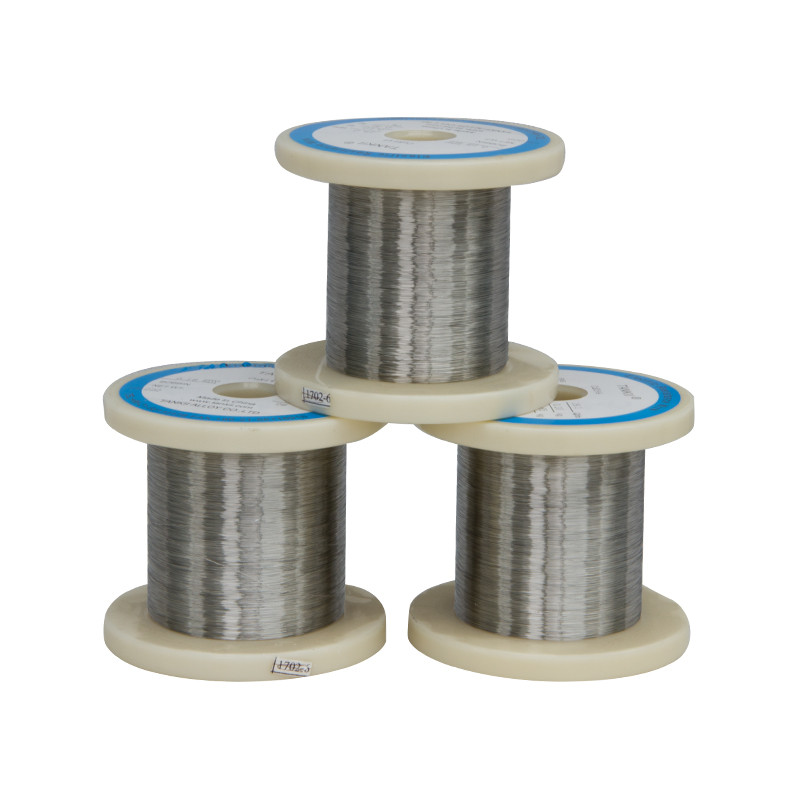

Vacon 12 Fe-Ni-Co Glass Sealing Alloy Wire Kovar Alloy Waya

Vacon 12Waya wa Aloi ya Kioo ya Fe-Ni-CoKovarWaya ya Aloi

(Jina la Kawaida:Kovar, Nilo K, KV-1, Dilver Po, Vacon 12)

Vipimo:Laha/Sahani, Mwamba/Fimbo/Waya/Koili,Kapilari/Bomba/Mrija

Safu ya Ukubwa:

—*Karatasi_Unene 0.1mm ~ 40.0mm, upana:≤300mm,Hali: baridi iliyoviringishwa(moto), angavu, inayong'aa

— * MzungukoWaya_Dia 0.1mm~Dia 5.0mm,Hali: inayotolewa kwa baridi, angavu, iliyochujwa

—*Waya Bapa_Dia 0.5mm~Dia 5.0mm,urefu:≤1000mm,Hali:gorofa iliyoviringishwa, inayong'aa

-*Bar_Dia 5.0mm~Dia 8.0mm,urefu:≤2000mm,Hali:inayochorwa kwa baridi,inang'aa, inang'aa

Dia 8.0mm~Dia 32.0mm,urefu:≤2500mm,Hali:iliyoviringishwa moto,inang'aa, inang'aa

Dia 32.0mm~Dia 180.0mm,urefu:≤1300mm,Hali:kughushi moto,kuchubuliwa, kugeuzwa, kutibiwa moto

—*Kapilari_OD 8.0mm~1.0mm,Kitambulisho 0.1mm~8.0mm,urefu:≤2500mm,Hali: inayotolewa kwa baridi, kung'aa, kung'aa

— * Bomba_OD 120mm~8.0mm,ID 8.0mm~129mm,urefu:≤4000mm,Hali: inayotolewa kwa baridi, angavu, inayong'aa

Maombi:

Hasa hutumika katika vipengele vya utupu wa umeme na udhibiti wa chafu, tube ya mshtuko, tube ya kuwasha, magnetron ya kioo, transistors, kuziba muhuri, relay, risasi ya nyaya zilizounganishwa, chasi, mabano na kuziba nyingine za makazi.

Utunzi wa kawaida

| Ni | 28.5~29.5 | Fe | Bal. | Co | 16.8~17.8 | Si | ≤0.3 |

| Mo | ≤0.2 | Cu | ≤0.2 | Cr | ≤0.2 | Mn | ≤0.5 |

| C | ≤0.03 | P | ≤0.02 | S | ≤0.02 |

Nguvu ya mkazo, MPa

| Kanuni ya hali | Hali | Waya | Ukanda |

| R | Laini | ≤585 | ≤570 |

| 1/4I | 1/4 ngumu | 585~725 | 520~630 |

| 1/2I | 1/2 ngumu | 655~795 | 590-700 |

| 3/4I | 3/4 ngumu | 725~860 | 600-770 |

| I | Ngumu | ≥850 | ≥700 |

Tabia za kawaida za Kimwili

| Uzito (g/cm3) | 8.2 |

| Ustahimilivu wa umeme kwa 20ºC(Ωmm2/m) | 0.48 |

| Kipengele cha halijoto cha kustahimili upinzani (20ºC~100ºC)X10-5/ºC | 3.7~3.9 |

| Sehemu ya Curie Tc/ºC | 430 |

| Modulus Elastic, E/Gpa | 138 |

Mgawo wa upanuzi

| θ/ºC | α1/10-6ºC-1 | θ/ºC | α1/10-6ºC-1 |

| 20-60 | 7.8 | 20-500 | 6.2 |

| 20-100 | 6.4 | 20-550 | 7.1 |

| 20-200 | 5.9 | 20-600 | 7.8 |

| 20-300 | 5.3 | 20-700 | 9.2 |

| 20-400 | 5.1 | 20-800 | 10.2 |

| 20-450 | 5.3 | 20-900 | 11.4 |

Conductivity ya joto

| θ/ºC | 100 | 200 | 300 | 400 | 500 |

| λ/ W/(m*ºC) | 20.6 | 21.5 | 22.7 | 23.7 | 25.4 |

| Mchakato wa matibabu ya joto | |

| Annealing kwa unafuu wa dhiki | Imepashwa joto hadi 470~540ºC na ushikilie kwa saa 1~2. Baridi chini |

| annealing | Katika ombwe lenye joto hadi 750~900ºC |

| Kushikilia wakati | 14 dakika ~ 1h. |

| Kiwango cha baridi | Isizidi 10 ºC/dak kilichopozwa hadi 200 ºC |

Kategoria za bidhaa

-

Simu

-

Barua pepe

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Juu