Karibu kwenye tovuti zetu!

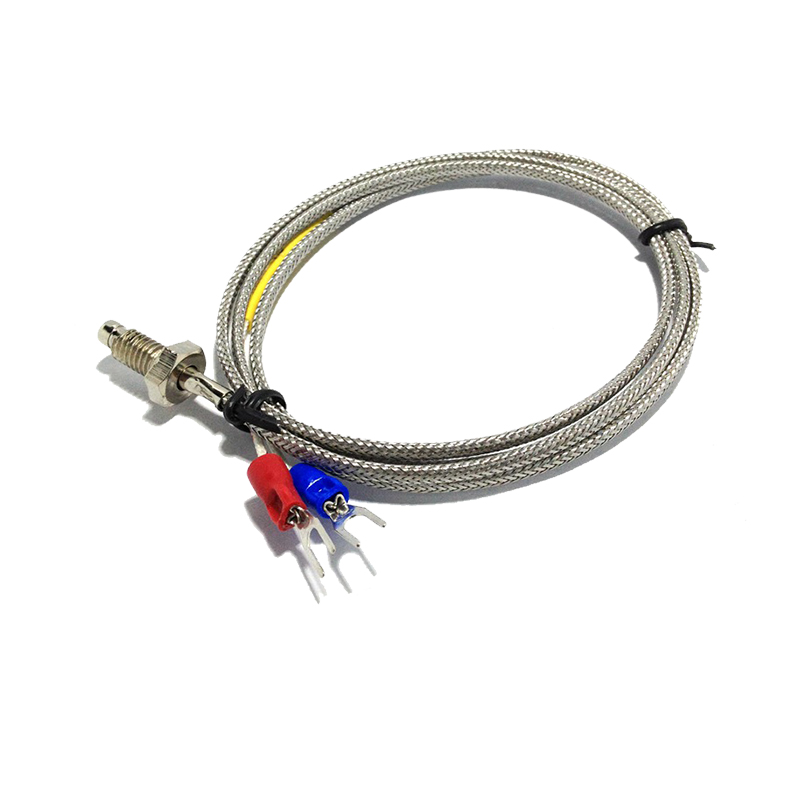

Waya ya Upinzani wa Kupasha Joto ya X20h80 (Nicr80/20)

| Muundo wa Kemikali na Sifa: | ||||

| Sifa/Daraja | NiCr 80/20 | NiCr 70/30 | NiCr 60/15 | |

| Muundo Mkuu wa Kemikali (%) | Ni | Bal. | Bal. | 55.0-61.0 |

| Cr | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | |

| Fe | ≤ 1.0 | ≤ 1.0 | Bal. | |

| Joto la Juu la Kufanya Kazi (ºC) | 1200 | 1250 | 1150 | |

| Upinzani katika 20ºC(μΩ · m) | 1.09 | 1.18 | 1.12 | |

| Uzito (g/cm3) | 8.4 | 8.1 | 8.2 | |

| Upitishaji joto (KJ/m· h· ºC) | 60.3 | 45.2 | 45.2 | |

| Mgawo wa Upanuzi wa Joto (α × 10-6/ºC) | 18 | 17 | 17 | |

| Kiwango cha Kuyeyuka (ºC) | 1400 | 1380 | 1390 | |

| Urefu (%) | > 20 | > 20 | > 20 | |

| Muundo wa Mikrografiki | austenite | austenite | austenite | |

| Sifa ya Sumaku | isiyo na sumaku | isiyo na sumaku | isiyo na sumaku | |

| Sifa/Daraja | NiCr 35/20 | NiCr 30/20 | Karma | Evanohm | |

| Kemikali Kuu Muundo(%) | Ni | 34.0-37.0 | 30.0-34.0 | Bal | Bal |

| Cr | 18.0-21.0 | 18.0-21.0 | 19.0-21.5 | 19.0-21.5 | |

| Fe | Bal. | Bal. | 2.0-3.0 | - | |

| Joto la Juu la Kufanya Kazi (ºC) | 1100 | 1100 | 300 | 1400 | |

| Upinzani katika 20ºC (μΩ · m) | 1.04 | 1.04 | 1.33 | 1.33 | |

| Uzito (g/cm3) | 7.9 | 7.9 | 8.1 | 8.1 | |

| Uendeshaji wa joto (KJ/m· h· ºC) | 43.8 | 43.8 | 46 | 46 | |

| Mgawo wa joto Upanuzi(α × 10-6/ºC) | 19 | 19 | - | - | |

| Kiwango cha Kuyeyuka (ºC) | 1390 | 1390 | 1400 | 1400 | |

| Urefu (%) | > 20 | > 20 | 10-20 | 10-20 | |

| Muundo wa Mikrografiki | austenite | austenite | austenite | austenite | |

| Sifa ya Sumaku | isiyo na sumaku | isiyo na sumaku | isiyo na sumaku | isiyo na sumaku | |

| Muundo wa Kemikali | Nikeli 80%, Chrome 20% |

| Hali | Rangi angavu/nyeupe yenye asidi/iliyooksidishwa |

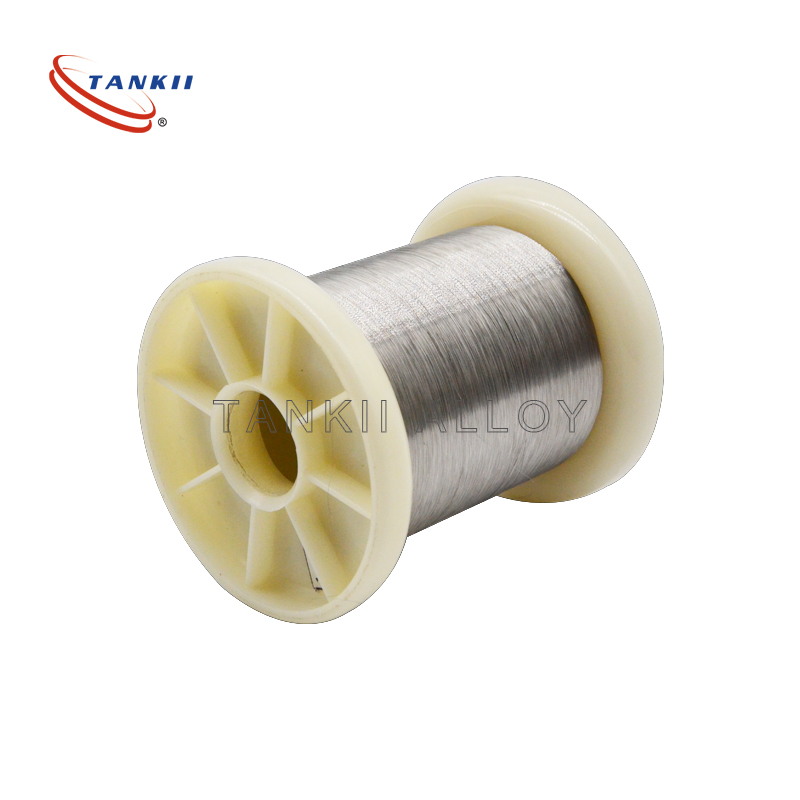

| Kipenyo | 0.018mm ~ 1.6mm kwenye spool, 1.5mm-8mm kwenye coil, 8~60mm kwenye fimbo |

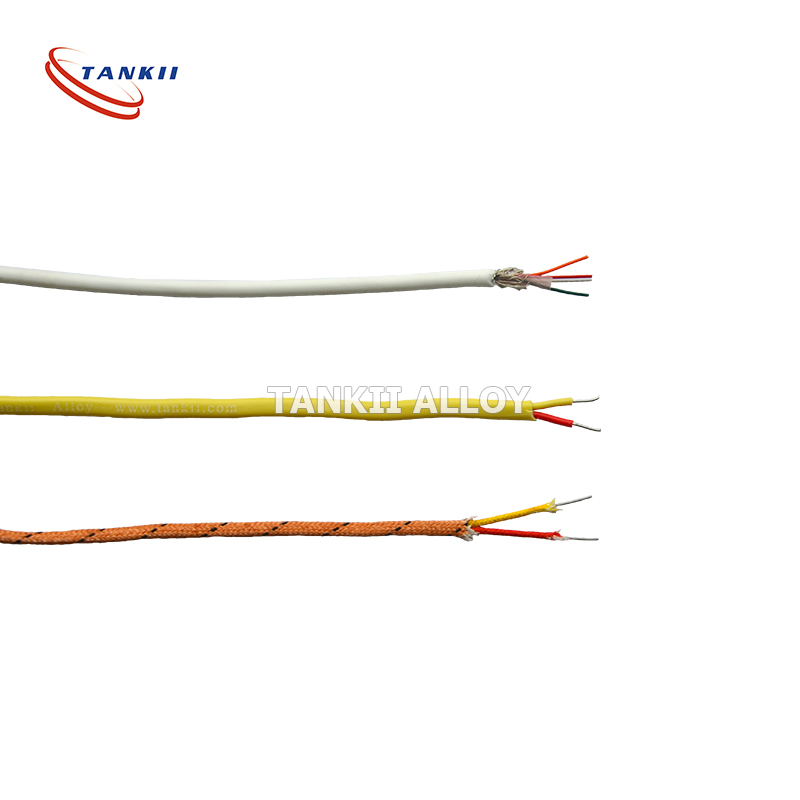

| Waya wa Mzunguko wa Nichrome | Kipenyo 0.018mm ~ 10mm |

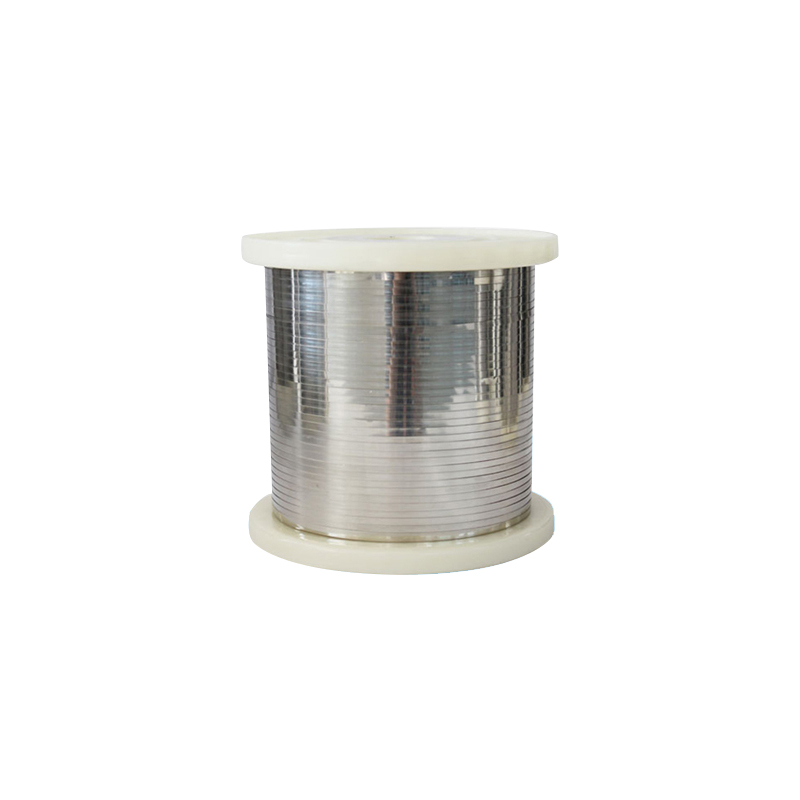

| Utepe wa Nichrome | Upana 5 ~ 0.5mm, unene 0.01-2mm |

| Ukanda wa Nichrome | Upana 450mm ~ 1mm, unene 0.001m ~ 7mm |

| Kipenyo | Ufungashaji wa 1.5mm-8mm kwenye koili, 8~60mm kwenye fimbo |

| Daraja | Ni80Cr20, Ni70/30, Ni60Cr15, Ni60Cr23, Ni35Cr20Fe, Ni30Cr20 Ni80, Ni70, Ni60, Ni40, |

| Faida | Muundo wa metallurgiska wa nichrome huwapa unyumbufu mzuri sana wakati wa baridi. |

| Sifa | Utendaji thabiti; Kupambana na oksidi; Upinzani wa kutu; Utulivu wa halijoto ya juu; Uwezo bora wa kutengeneza koili; Hali ya uso yenye sare na nzuri bila madoa. |

| Matumizi | Vipengele vya kupokanzwa vya upinzani; Nyenzo katika madini, Vifaa vya nyumbani; Utengenezaji wa mitambo na viwanda vingine. |

| Waya za Upinzani | ||

| RW30 | Nambari ya W.Nr 1.4864 | Nikeli 37%, Chrome 18%, Chuma 45% |

| RW41 | UNS N07041 | Nikeli 50%, Chrome 19%, Kobalti 11%, Molybdenum 10%, Titanium 3% |

| RW45 | Nambari ya W.r 2.0842 | Nikeli 45%, Shaba 55% |

| RW60 | Nambari ya W.r 2.4867 | Nikeli 60%, Chrome 16%, Chuma 24% |

| RW60 | UNS NO6004 | Nikeli 60%, Chrome 16%, Chuma 24% |

| RW80 | Nambari ya W.r 2.4869 | Nikeli 80%, Chrome 20% |

| RW80 | UNS NO6003 | Nikeli 80%, Chrome 20% |

| RW125 | Nambari ya W.r 1.4725 | Chuma cha BAL, Chrome 19%, Alumini 3% |

| RW145 | Nambari ya W.N 1.4767 | Chuma cha BAL, Chrome 20%, Alumini 5% |

| RW155 | Chuma cha BAL, Chrome 27%, Alumini 7%, Molybdenum 2% | |

Andika ujumbe wako hapa na ututumie

Aina za bidhaa

-

Simu

-

Barua pepe

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Juu